Food

Jonker & Schut

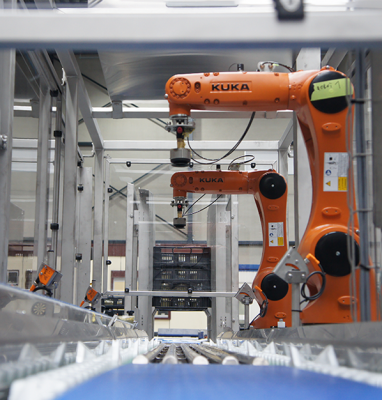

AVT Europe NV has built an installation capable of handling a total capacity of 800 bags per hour.

The installation consists of 2 robots with a gripper based on vacuum technology for the destacking of bags with a weight of 25 kg.

The operator enters a pallet using the chain conveyors after which the further cycle is fully automatic.

In order to achieve sufficient capacity and allow recipes, there are 4 feeding lines and a total of 16 pallet positions.

The intelligent vision system of our partner Fizyr detects the position of the bags on the pallet. The exact coordinates are transmitted and then the KUKA robot can unstack the bags and place them on the conveyor belt for further processing. The major advantage of this vision system is that it works completely pattern independent. The operator only has to enter the number of bags and the system finds the right position and orientation, regardless of the stacking pattern.

Each robot can de-stack bags in 2 positions. When the pallet is completely empty, it is moved by means of a scissor table to an underlying chain conveyor and discharged.

The destacking robot is a standardized solution of AVT Europe NV which is always applied according to the needs of our customers.