Steel and cables

Aurubis

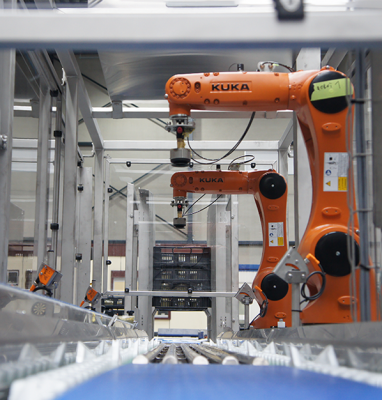

Robot plant for automatic sampling on 500kg sheets of recycled copper.

Challenge

Incoming lots of copper anodes and blister anodes must be drilled to take a sample, following a certain pattern and procedure. It is very important that the samples from the different lots are not mixed or contaminated in order to obtain a correct analysis per lot or sublot. The collected samples are further processed in the fine preparation before being sent to the lab. This process was performed completely manually and with outdated tools by operators.

Incoming lots of copper anodes and blister anodes must be drilled to take a sample, following a certain pattern and procedure. It is very important that the samples from the different lots are not mixed or contaminated in order to obtain a correct analysis per lot or sublot. The collected samples are further processed in the fine preparation before being sent to the lab. This process was performed completely manually and with outdated tools by operators.

Solution

The operator uses a forklift to place a stack of anodes into the robotic system. By means of a walking beam conveyor, the stacks are moved up to the robot.

The operator uses a forklift to place a stack of anodes into the robotic system. By means of a walking beam conveyor, the stacks are moved up to the robot.

The robot with custom-made gripper takes an anode plate (500kg) and brings it to above a specially designed drilling unit. The chips from the drilling process are collected in a tray and serve as samples. A 2nd robot manages the rack with collection trays for the samples and can automatically change the drills in the drilling unit.